规格

The M1 will swage MS type terminals onto galvanized and stainless steel cables from 1/16″ diameter up to and including 3/16″ diameter.

符合 MIL 规范 MIL-S-6180。

Shipping Weight: 54 Lbs.

Cableware®部门 / 锻压机 / Locoloc® M1 - I 型

有用的信息:

绞车指南》中的正确压接技术

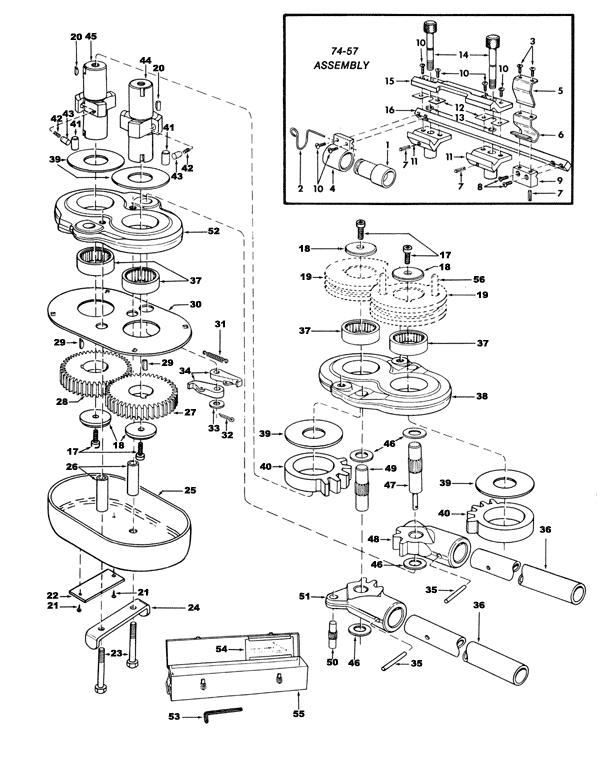

M1 HAND SWAGING MACHINE

Type I – Portable Manual Swaging Machine – Part No. M1

This portable, hand operated roll type swaging machine, will swage MS type terminals onto galvanized and stainless steel cables from 1/16″ diameter up to and including 3/16″ diameter. Marine-industrial terminals can also be assembled if the terminals have the same outside diameter and bore diameters as standard MS terminals before swaging.

Available in kit (M1-K) complete with swaging machine and dies or machine and dies can be purchase separately.

下载 a copy of the operator’s manual.

查看我们的 HOW TO: 锻压机

美国制造:是

The M1 will swage MS type terminals onto galvanized and stainless steel cables from 1/16″ diameter up to and including 3/16″ diameter.

符合 MIL 规范 MIL-S-6180。

Shipping Weight: 54 Lbs.

在 1 x 19 结构的钢丝绳上安装接头时,请记住这种结构的钢丝绳几乎没有压缩力。钢丝绳本身非常坚固,几乎没有 "松动"。

1 x 19 结构的钢丝绳在公差 "偏高 "的情况下制造,而接头的孔在公差 "偏低 "的情况下运行(见规格下的接头尺寸),两者结合会使问题更加严重。请记住,预装机必须有足够的空间让接头中的钢材 "流动 "或 "移动",以围绕钢丝绳成型。必须有足够的空间来实现这一目标。

In addition, many manufacturers do not drill the hole in their fittings deep enough. This leaves a space at the base of the fitting of solid steel. This distance can vary from 1/4″ up to over 1″. The Locoloc® Kearney machine simply cannot perform the impossible and swage solid metal, again there must be room for the steel to “flow” or “move”.

如果出现上述任何一种情况,结果只能是模具损坏、机器窜动、配件毁坏,甚至可能损失昂贵的钢丝绳。在尝试进行压接之前,只要检查以下几点,就可以轻松避免大多数情况的发生:

清洁:

不能让灰尘、污垢或其他外来物质聚集在弯管机上;它们最终会进入机械装置,造成过度磨损和损坏。

在安装一组辊模之前,用干净的软布仔细擦拭其活性表面,以确保不会有砂粒弄脏辊模表面。

顽固的油脂或其他粘性物质通常可以用石油基溶剂擦拭去除。

润滑:

每台弯管机在工厂组装时都已加注润滑油,此后无需定期润滑。如果要拆卸机器进行修理或大修,应使用溶剂将轴承和齿轮齿上的旧润滑脂清除干净,然后在这些部件上轻轻涂上 MIL-G-7118 或同等规格的极压低温润滑脂。

防腐蚀:

If the swaging machine is located in a dusty or humid environment, it is recommended that a hood of fairly heavy vinyl or canvas be used to cover it when it is not in use.

必须避免赤手接触辊模的工作表面,以防止指印腐蚀。

每次从预装机中取出一套辊模,都应在辊模和机器轴的外露部分轻轻涂上干净的防腐蚀油。

| Ref. No | Old Part No. | Description | Qty. |

|---|---|---|---|

| -1 | 13781-1M | Socket - Medium | 1 |

| 13781-1S | Socket - Small | 1 | |

| -2 | 13773 | Retainer - Socket | 1 |

| -3 | 62338-04 | Screw - Round head, machine, steel zinc plated, No. 8-3 x 1/4 inch long | 2 |

| -4 | 13778 | Bracket - Socket | 1 |

| -5 | 13780-1 | Clip-Front | 1 |

| -6 | 13780 | Clip-Back | 1 |

| -7 | 66103-8 | Pin - Sel-Lok spring, 5/32 x 1/2 inch long | 3 |

| -8 | 62138-07 | Screw - Round head, machine, steel , zinc plated, No. 8-32 x 7/16 inch long | 2 |

| -9 | 13779 | Adapter | 1 |

| -10 | 62338-08 | Screw - Round head, machine, steel, zinc plated, No. 8-32 x 1/2 inch long | 6 |

| -11 | 13774 | Post-V-way | 2 |

| -12A | 13776 | Shim .003" | AR |

| -12B | 13776-1 | Shim .005" | AR |

| -12C | 13776-2 | Shim .015" | AR |

| -13 | 13776-3 | Retainer | 2 |

| -14 | 13772 | Screw-Allen Head Cap | 2 |

| -15 | 13771 | Cover - V-way | 1 |

| -16 | 13775 | Slide | 1 |

| -17 | 62449-10 | Screw - Allen head, cap, steel 5/16-24 x 5/8 inch long | 4 |

| -18 | 9546 | washer | 4 |

| -19 | -- | Roll Assemblies (For details see Table 1-1) | - |

| -20 | 13227-1 | Key- Woodruff | 2 |

| -21 | 62569-03 | Screw - Drive, stainless steel, No. 4 x 3/16 inch long | 2 |

| -22 | 1330-10 | Plate - Name | 1 |

| -23 | 62449-32 | Screw - Allen , cap, steel, 5/16-24 x 2 inch long | 2 |

| -24 | 20436 | Rest - Foot | 1 |

| -25 | 12949 | Gear - Cover | 1 |

| -26 | 20435 | 套筒 - 齿轮箱体 | 2 |

| -27 | 12962 | 齿轮 - 下部 | 1 |

| -28 | 12961 | 齿轮 - 上齿轮 | 1 |

| -29 | 13227 | 钥匙 - 伍德拉夫 | 2 |

| -30 | 20437 | 板 - 齿轮箱体 | 1 |

| -31 | 13224 | 弹簧 - 张力 | 1 |

| -32 | 60916-08 | 销 - 开口销,1/16 x 1/12 英寸长 | 1 |

| -33 | 13229 | 垫圈 - 锁销 | 1 |

| -34 | 13223 | 闩锁-反向 | 2 |

| -35 | 9552 | 铆钉 - 手柄 | 2 |

| -36 | 9555 | 手柄 | 2 |

| -37 | 63842-2 | 轴承 - 滚子,麦吉尔 SK-5881 | 4 |

| -38 | 9536-2 | 板 - 前部 | 1 |

| -39 | 13036 | 垫圈 - 推力 | 4 |

| -40 | 9538 | 戒指 - 手环 | 2 |

| -41 | 9542 | 滚筒 - 离合器 | 8 |

| -42 | 9544 | 弹簧 - 离合器滚子 | 8 |

| -43 | 9543 | 支架 - 弹簧 | 8 |

| -44 | 9547-1 | 轴 - 下卷 | 1 |

| -45 | 9548-1 | 轴 - 上卷 | 1 |

| -46 | 13034 | 垫圈 - 垫片 | 4 |

| -47 | 13023 | 轴 - 驱动小齿轮,左侧 | 1 |

| -48 | 9539 | 小齿轮 - Drife,左 | 1 |

| -49 | 9541 | 轴 - 驱动小齿轮,右侧 | 1 |

| -50 | 13228 | 针脚 - 停止 | 1 |

| -51 | 9540 | 销 - 驱动器,右侧 | 1 |

| -52 | 9537-2 | 板 - 背面 | 1 |

| -53 | 64386-07 | 扳手 - 1/4 英寸内六角扳手 | 1 |

| -54 | INST-01 | 使用手册 | 1 |

| -55 | 13658 | 外壳 - 携带 | 1 |

| -56 | 销钉--黑色螺旋钢。1/4 x 1/4 英寸 | 2 | |

| 74-57 | 13656 | 进料导向组件(包含 74-1 至 74-16 号零件) | 1 |

保修限制信息:

Loos & Co. 公司对所有 Locoloc® 卡尼机器的保修仅限于使用 Locoloc® 接头,以充分保证我们机器的性能。对于其他制造商生产的洛氏硬度超过 62、A 级或 RB100 的配件造成的机器损坏,我们概不负责。

很明显,Locoloc® Kearney 机器将压接的某些接头是我们不提供或不能提供的。在这种情况下,我们要求您检查管接头的硬度,以确定最大洛氏硬度为 62 A 级,同样,如果其他制造商生产的管接头的洛氏硬度超过 62 A 级或 RB100,造成机器损坏,我们概不负责。